Construction specifications

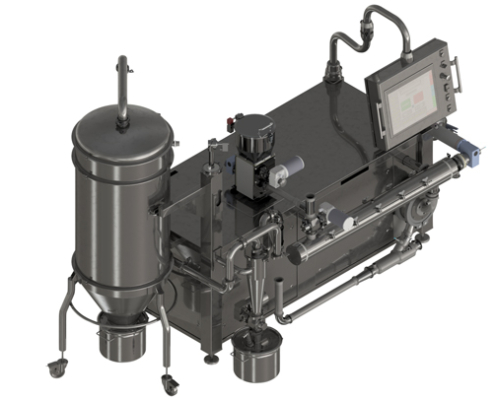

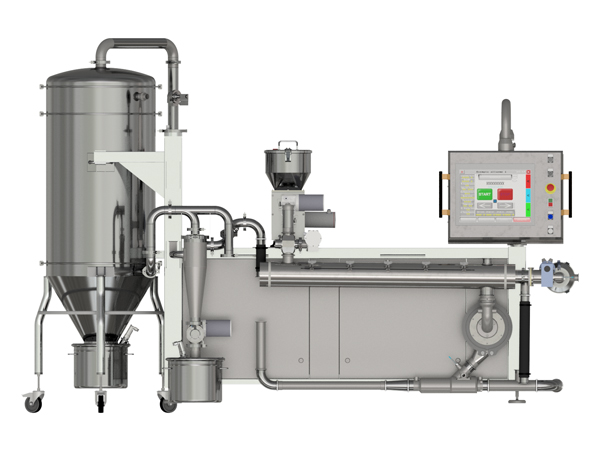

Zero Line is a multi-function pilot plant, which is highly innovative from a technical point of view.

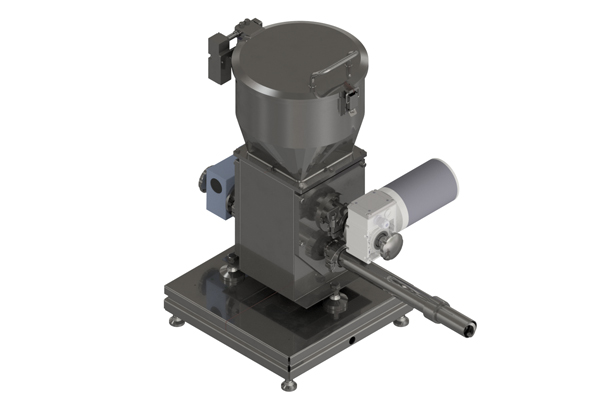

The operating principle of the machines installed on the worktable is exactly the same principle of the machines for industrial productions. The plant is formed by interchangeable grinding and selection tools: one emplacement to use several grinding systems.

The machine has a worktable especially designed to combine technical equipment, grinding and selection tools and electronic devices, following the production process thanks to high engineering standards and updated technology.

It also has a Touch Screen interface, as well as a highly efficient pilot mill, where you can vary the working tools or use the equipment for a room temperature processing, or for the cryogenic cycle.

Operational principle

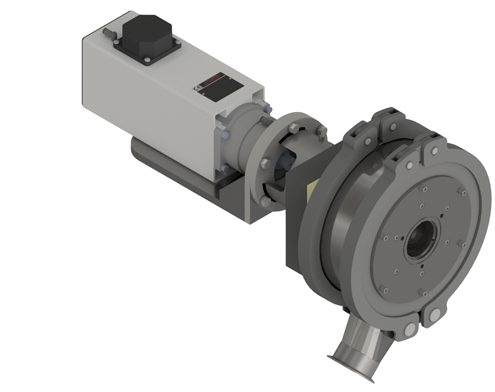

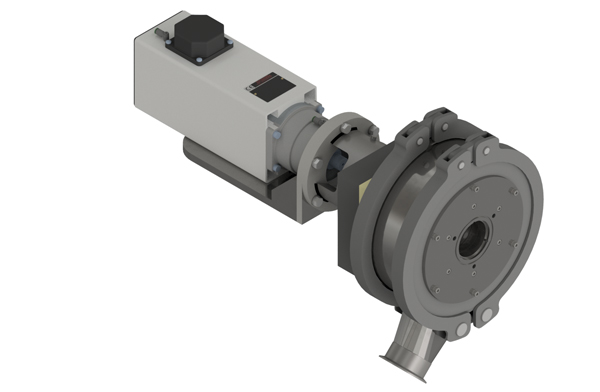

The machine functioning and the structure of the working chamber allow the user to apply cryogenic grinding or cryo-powdering to grind products which are usually too firm to be worked at room temperature. Cryogenic grinding, in fact, makes materials fragile.

Cryogenic grinding is cheap and has been successfully used in the grinding of waste coming from elastomers, plastic materials, and in all those branches where cryogenics blocks the organoleptic, physical and chemical characteristics which necessarily need to be maintained in the end product.

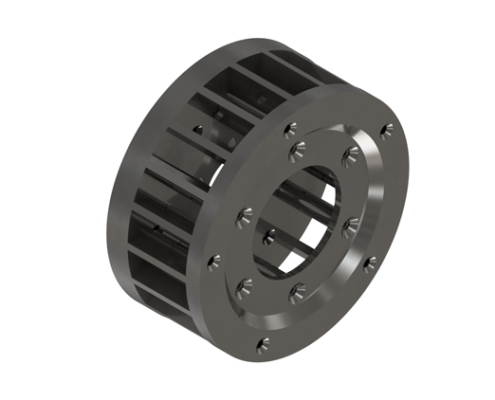

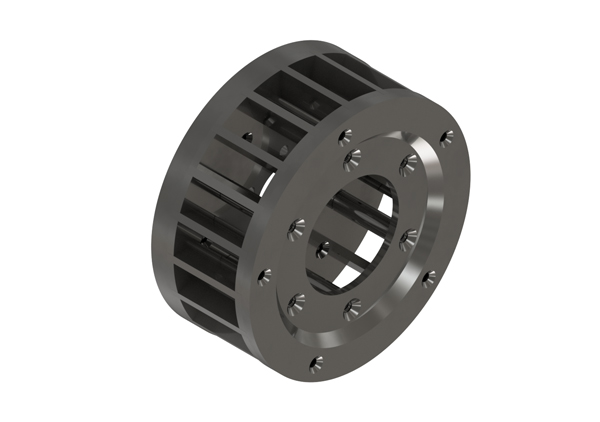

The user adds the material between a fix disk and a rotating one, both provided with steel rods lines. Grinding occurs by collision, without selecting the product. Granulometry is determined by the space among rods and by rotation speed.

Cryogenic application – Liquid Nitrogen

Liquid nitrogen has three main functions:

- it cools down the material to embrittlement temperature before grinding.

- it maintains a constant temperature during the processing, absorbing heat coming from the grinding process

- in the grinding plant it produces an inert climate, which is extremely dry and absolutely non-toxic

The cryo-ground substances have physical characteristics which are different from those you will obtain by using traditional grinding processes. This is due to the different way in which the material structure is broken. Cryogenic embrittled substances produces, once ground, homogeneous grains, with a crystalline cubic shape; a room temperature grinding causes several lacerations in the original structure, due to the sliding of the crystalline plans, or to the particular reticular structures. The result is, therefore, a non-uniform powder.

Discover our installations around the world.

Discover our installations around the world.