Construction specifications

Suitable for the grinding of material with quartz content up to 6 %, a hardness up to 6 at the Mohs scale and particle sizes from 10 – 360 micron.

Suitable for nearly all kind of material; typical application is the big volume grinding of lime, dolomite, plaster, calcium, phosphate, minerals or similar raw material.

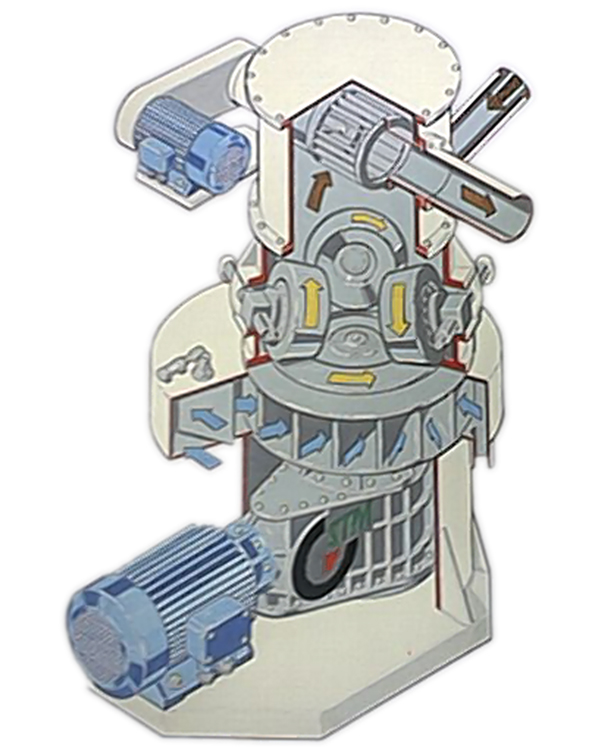

Operational principle

The high pressure rollers, moved forward by the rotating grinding track, and the material crushing achieve the grinding process.

The crushing pressure is adjustable in order to modify the material fineness and/or according to different material specifications.

The integrated classifier rejects particles of unwanted size and returns them automatically to the grinding process until the requested size is achieved.

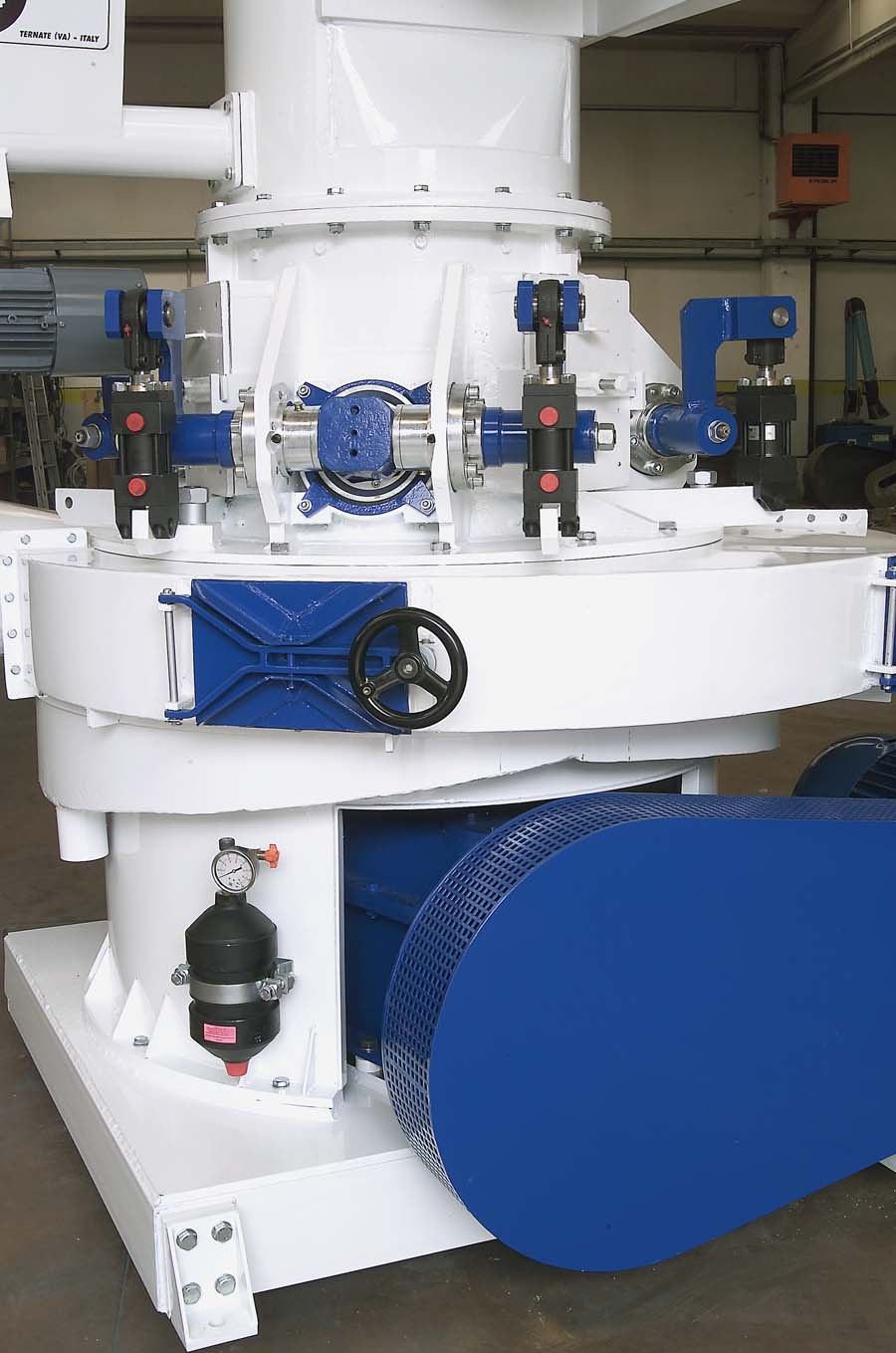

- Mill with conical grinding rollers for high pressure

- Hydraulically controlled pressure system

- Easy accessible hydraulic roller movement system

- Special roller and roller track material of reduced wear, which can be reconditioned by renewed surface hardening

- Roller bearings specially dust and powder protected

- Compact design of high capacity

Operational advantages

- Compact design

- Minimum space required

- Easy set-up

- Minimum maintenance

- Low energy consumption

- Withstands high stress

- MF Mill

Discover our installations around the world.

Discover our installations around the world.