The standard range of STM grinding and selection mills are suitable for plants producing large quantities on an industrial scale, where operational and performance parameters are generally measured in terms of reliability over time and relation of energy used to granulation quality and productivity.

However, there are certain market sectors where the interest is focused more on the quality of the end product, as well as small enterprises which are synthesizing new compounds, investigating new applications or preparing patent applications, and here the quantities required are limited to a few kilogrammes, or even a few grammes.

The Galileo line is the ideal solution for research and development, for producers using expensive ingredients in cosmetics, pharmaceutics, plastics, ceramics, specialized chemical products and other new materials, and where processing happens in small batches.

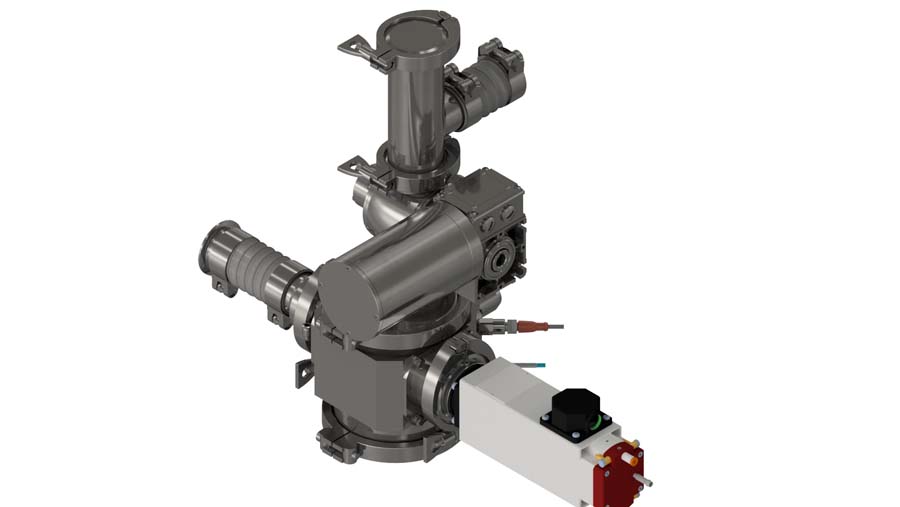

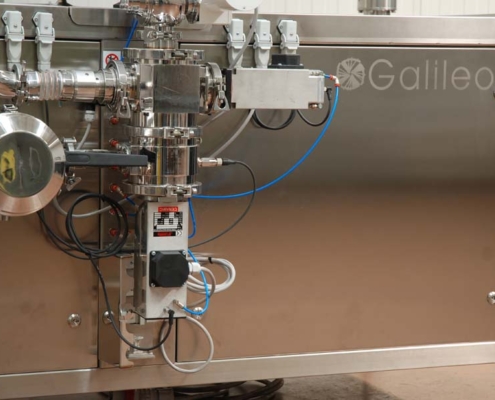

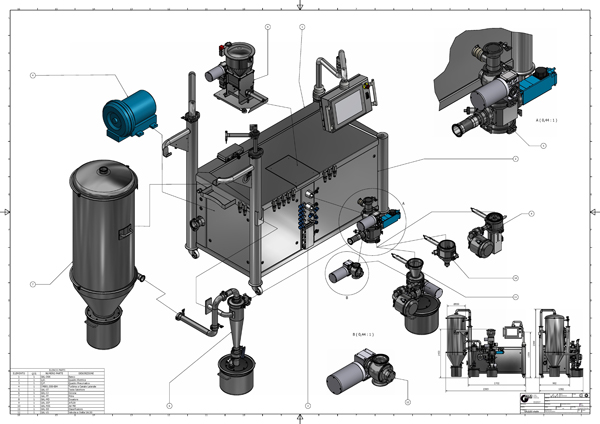

Galileo is a multi-function laboratory system which is highly innovative in technological terms.

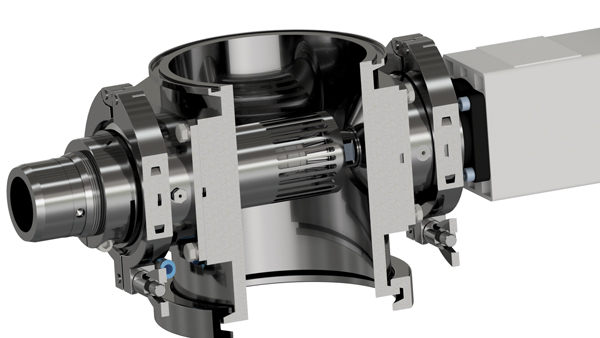

The operating principles of the Galileo counter-top machines are exactly the same as those of the industrial versions of the same machines.

This means that a client who trials micronization on a reduced scale has the guarantee of being able to transfer the laboratory process to an industrial-scale machine, thanks to an accurate and meticulous up-scaling of productive capacity.

Galileo Line: machines designed for…

- Ease of operation, with automatic recognition of devices installed

- Ease of use: the client is guided to introduce the required analytic objective and desired granulation, while the machine’s electro-mechanical parameters are regulated automatically.

- Ease of maintenance: interface with the control panel guides the tasks, methods and timing of maintenance.

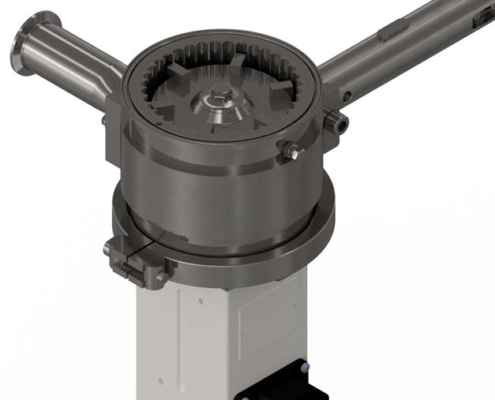

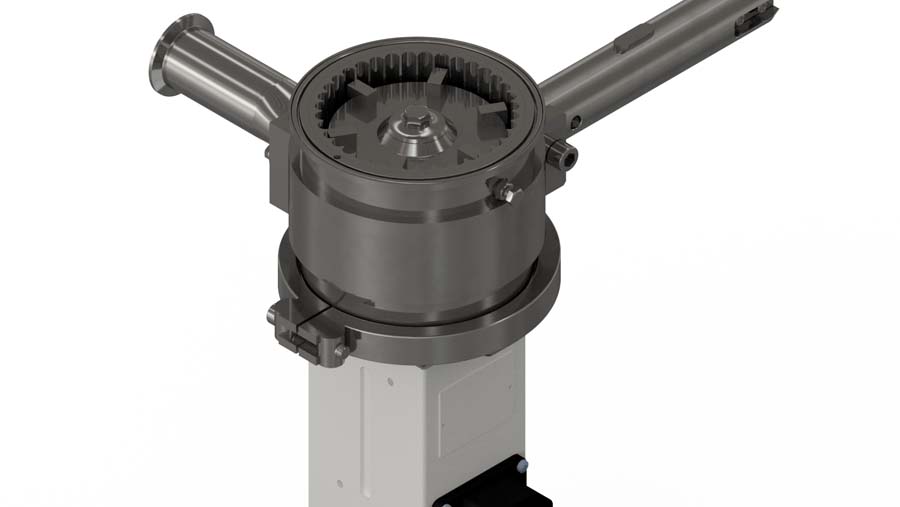

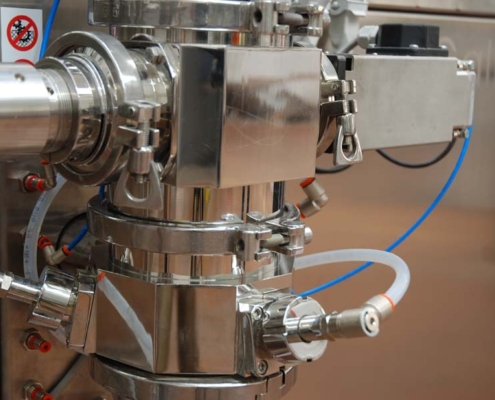

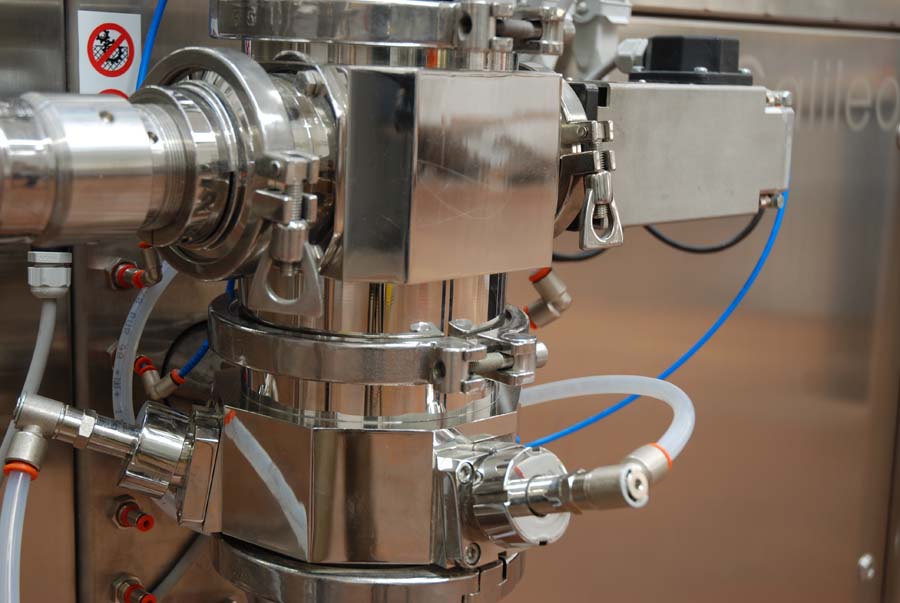

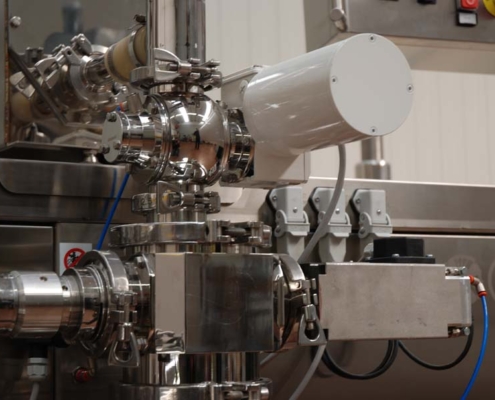

- Ease of cleaning: every component of the machine is designed to be easy to clean, with polished internal surfaces and no rough or inaccessible areas.

- Flexibility; ideal for initial phases of development of single components or compounds in powdered form.

- Low investment costs

Construction specifications

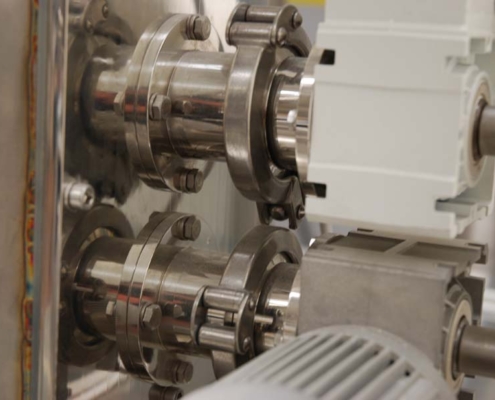

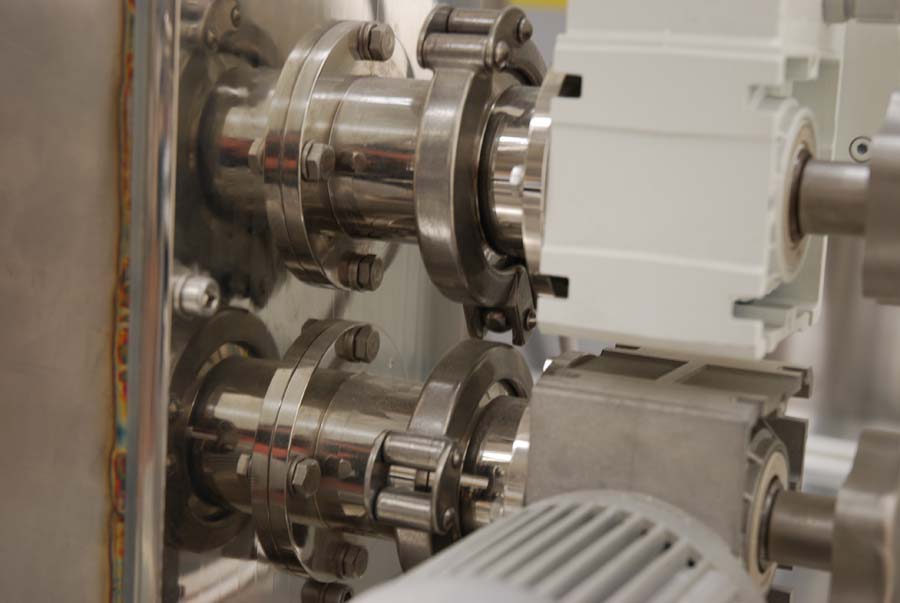

The equipment consists of a workbench with interchangeable grinding and selection tools, a single unit with three different machines, for R&D departments producing up to 10 kg/h, or minimum batches of 0.5 cubic decimetres of material.

The system comprises a series of 3 individual machines which are specially designed for small batches; the tools and electronic equipment used are of the highest standard of design and the technology is cutting-edge. The mechanical processes are integrated with a series of electronic devices which monitor the transformation of the material, analyse the parameters of the process and collect and analyse physical, chemical and mechanical data detected by the instruments during the grinding operation.

Discover our installations around the world.

Discover our installations around the world.