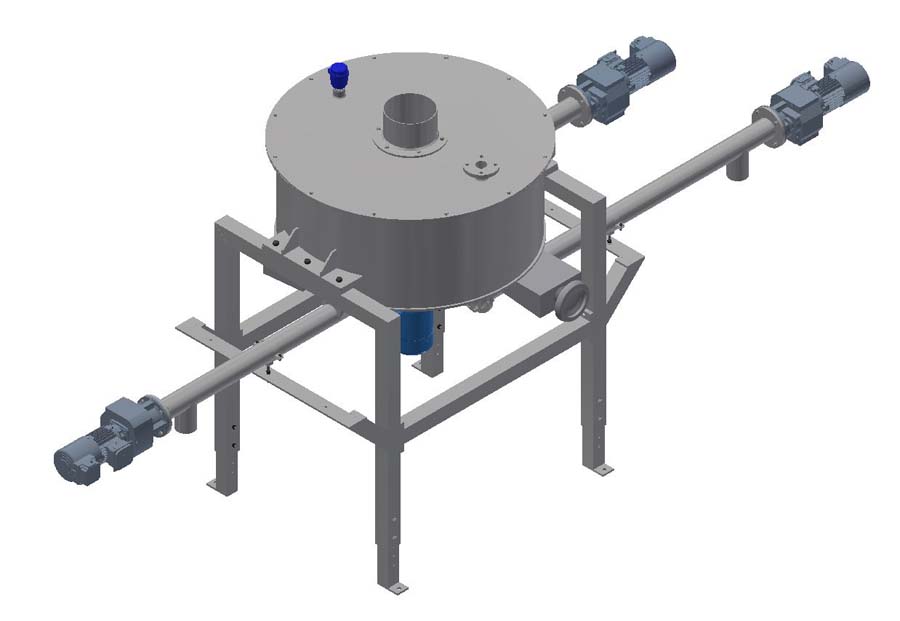

Construction specifications

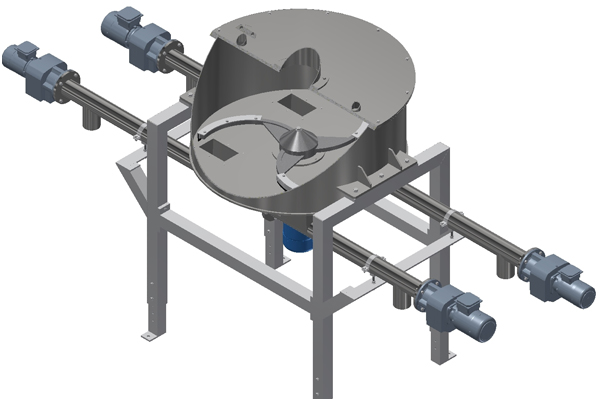

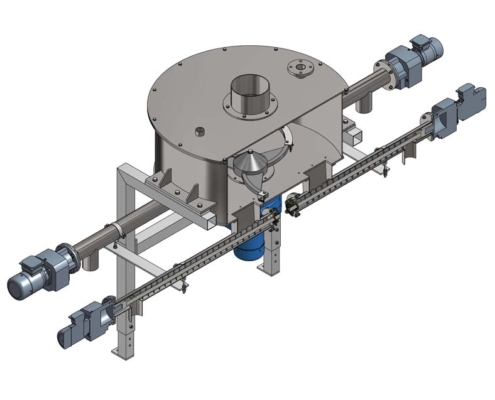

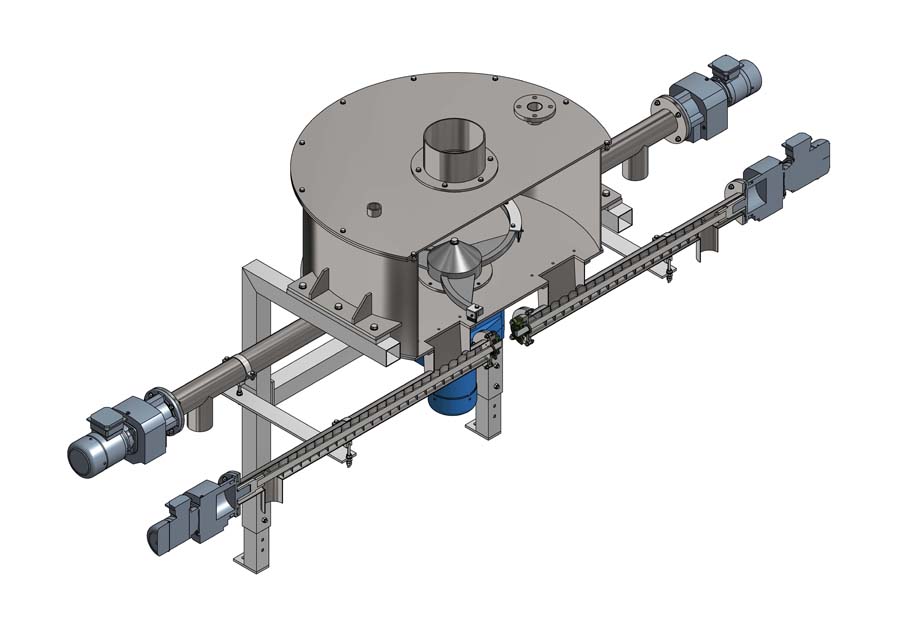

STM distribution chambers are suitable for a wide range of applications and solutions to dosage problems where more than one machine needs to be fed under the silo from a single primary storage source.

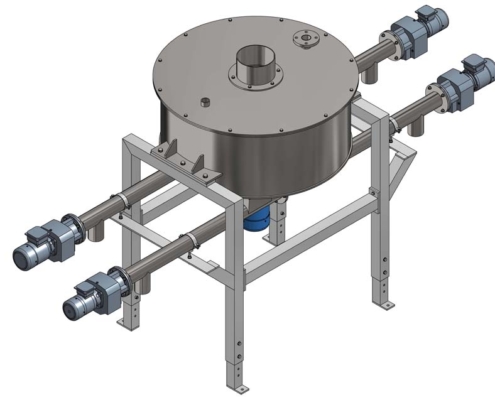

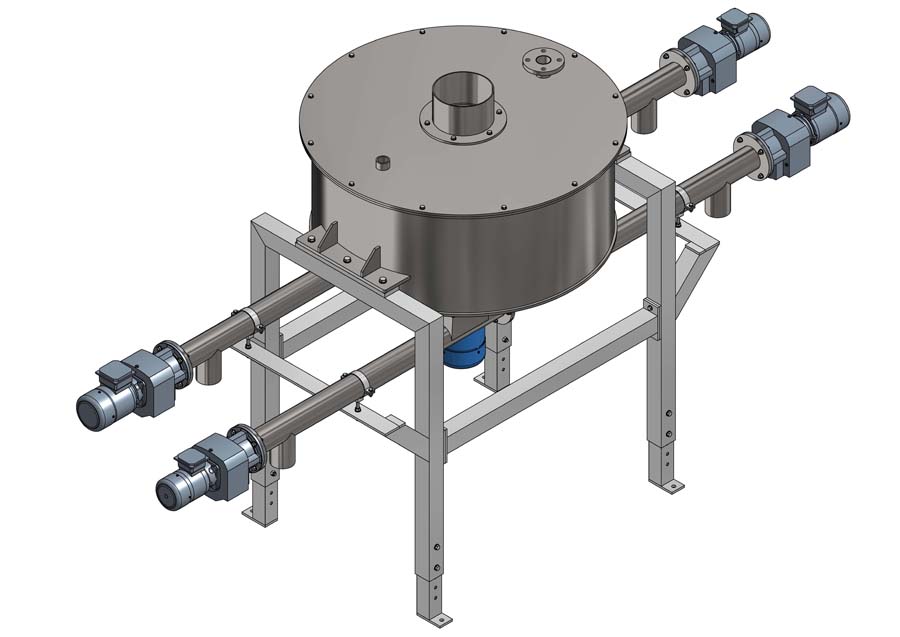

We supply modular machinery, adaptable in terms of number of outlets, size of screw feeders and speed of product extraction from the primary storage.

The distribution chamber is the simplest, yet most secure and efficient solution for the distribution of products which do not flow easily, or where considerations of installation and running costs dictate the splitting of product between several lines of machinery.

Operational principle

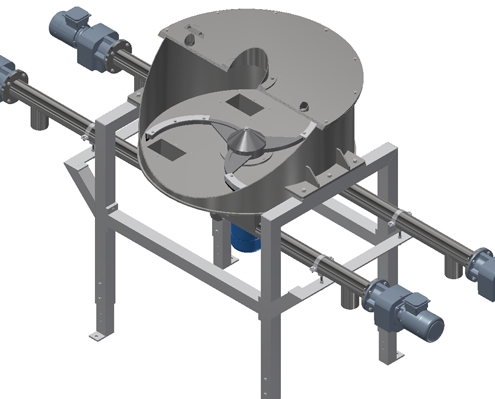

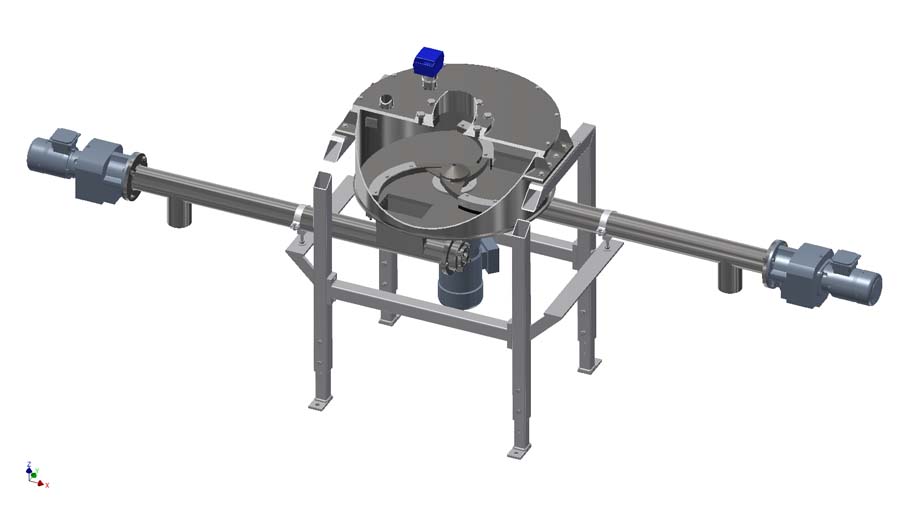

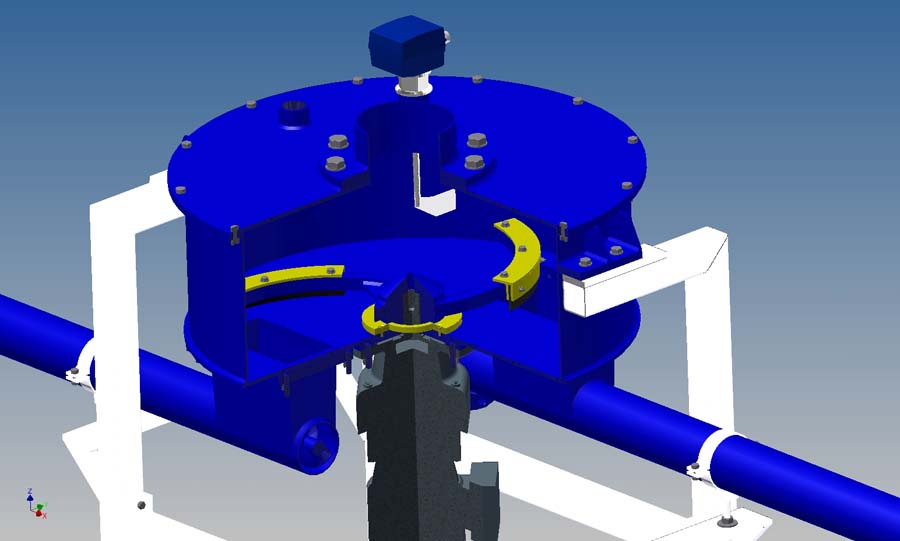

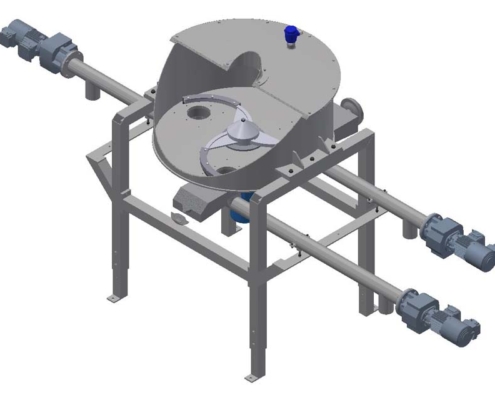

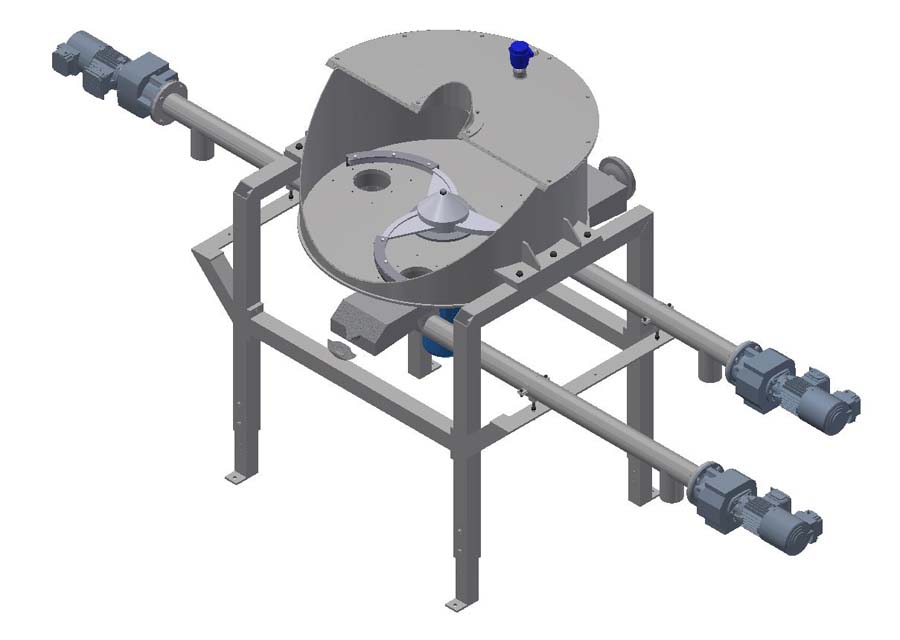

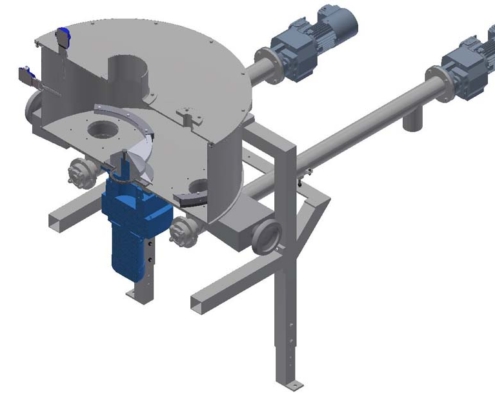

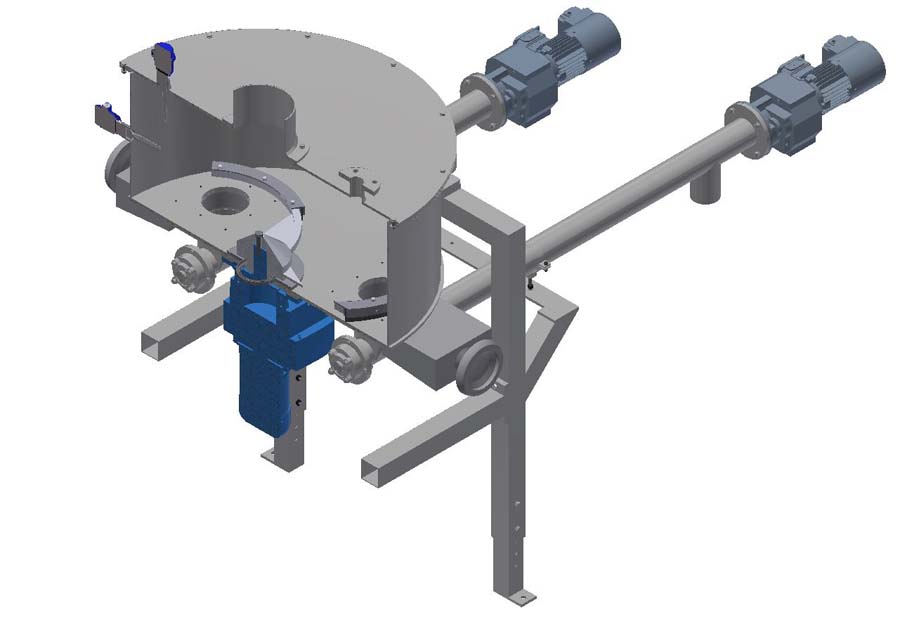

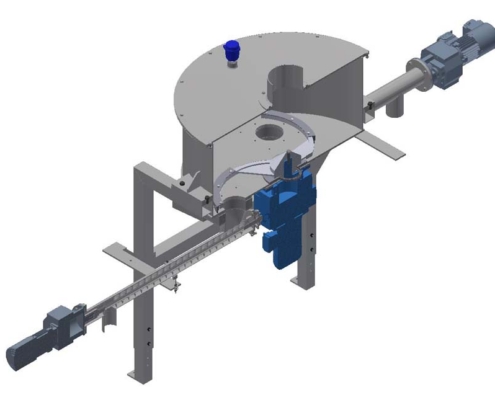

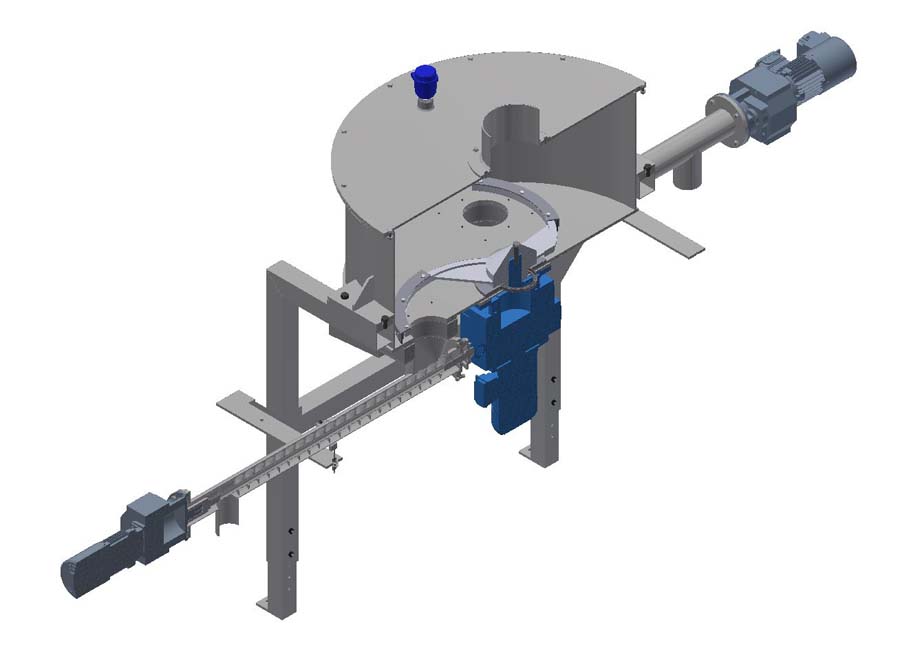

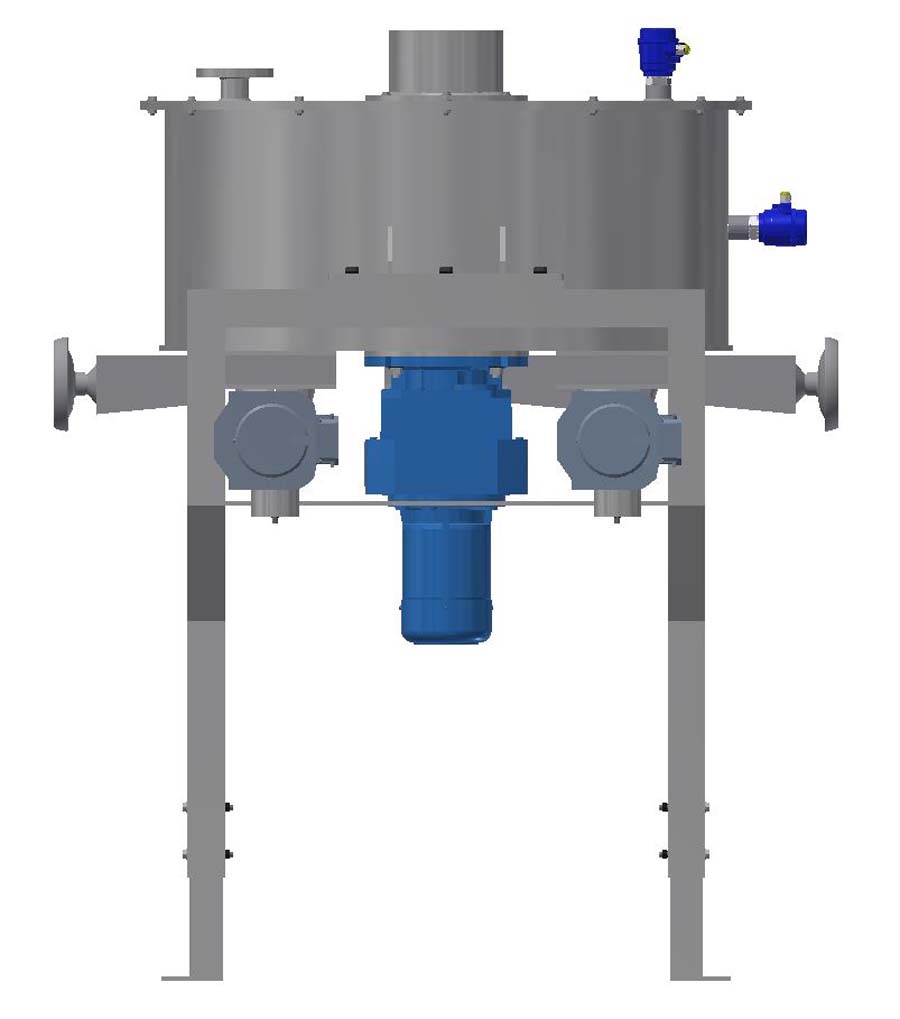

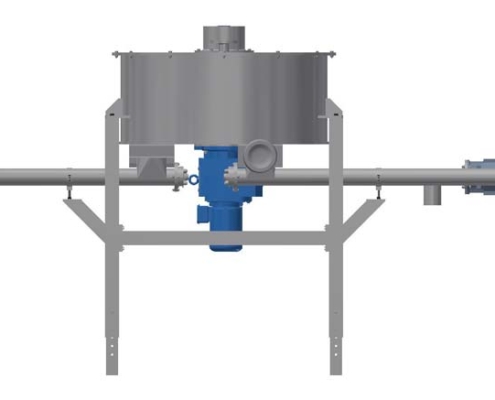

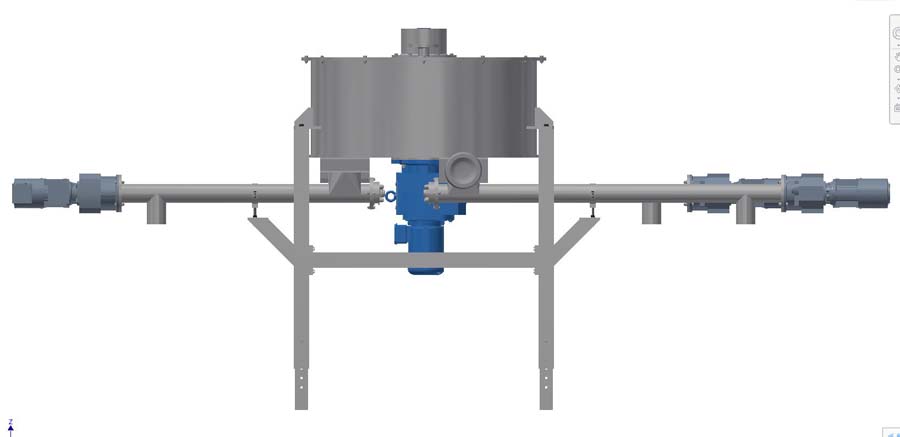

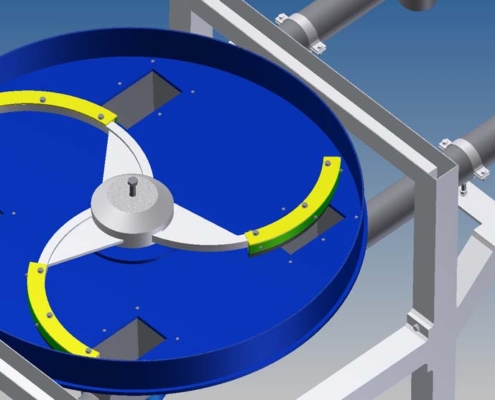

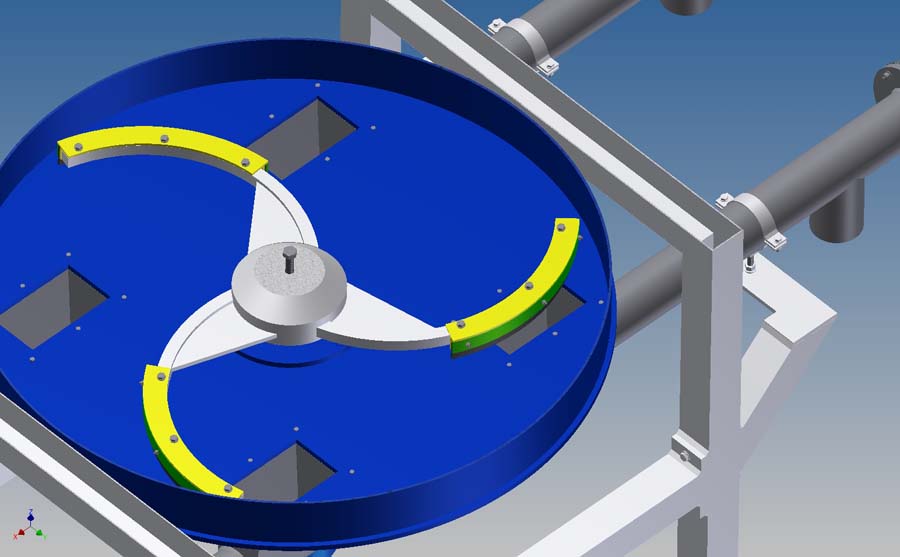

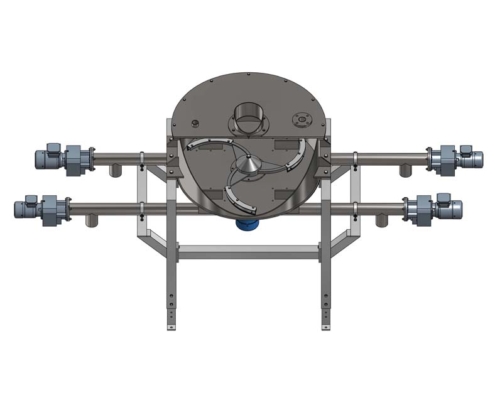

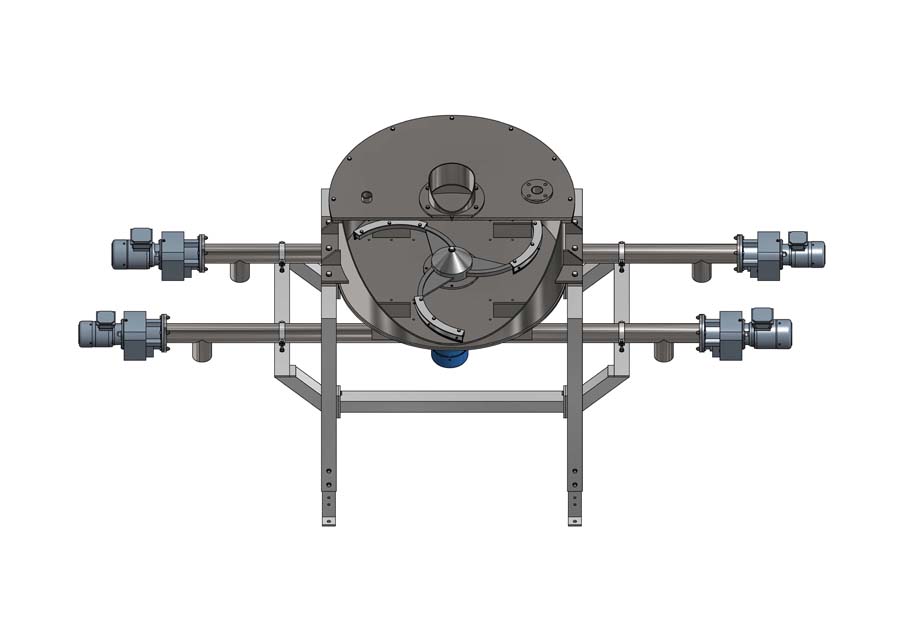

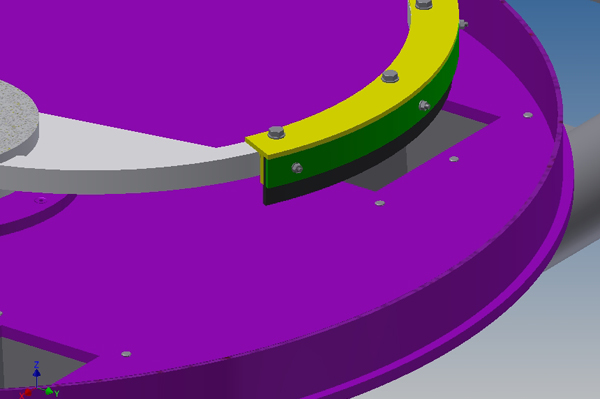

In simplified terms the machine consists of a feeder hopper positioned below the silo, coupled with a three-bladed rotary agitator reel which distributes the product to the outlets fitted with volumetric screw feeders for product extraction.

Inside the chamber is a conical diaphragm which ensures an even flow of product toward the screw feeders.

The chamber has a filter vent for air extraction and a hatch for inspection and fast replacement of the reel.

The chamber is connected to the screw feeders which transport the material from the chamber to the outlet star valves. Each screw feeder is fitted with a motor with crown and pinion gears and protective casing, the rotation is regulated by an inverter-controlled variator, which determines the dosage quantity.

The feed hopper is fitted with a sensor at palette level which controls the loading and discharge cycles and activates an alarm if the distribution system is obstructed.

Operational advantages

- Ease of installation

- Modular system, 2 ÷ 6 dosage outlets

- Can be coupled to existing machinery

- Enables several lines to be fed from a single primary store

- Optimal product distribution by weight and volume

- Ideal for products which do not flow easily

- Ease of maintenance

Discover our installations around the world.

Discover our installations around the world.