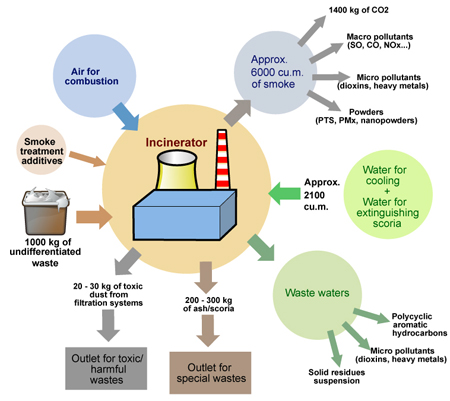

STM’s years of experience in the research and development of injection and reduction systems for various pollutants caused by industrial processes have enabled it to collaborate in improving the environmental outlook by meeting the most stringent regulatory criteria for gas emissions and industrial waste products.

In the field of dry grinding and depuration technology, we have developed and applied new systems for the reduction of pollutants, in collaboration with the technical departments of multinational companies.

Our machines, their applications and our standards of production, today represent a point of reference for reduction systems of pollution by acids, heavy metals, dioxins and furans, with meticulous ongoing research.

With its extensive experience in the sector, STM is able to evaluate and identify the most effective reduction system, both in terms of productive efficiency and running and maintenance costs.

A pollution reduction plant has a variable range of reagent injection; from the calculated nominal consumption, we supply all technical and system data necessary to ensure the plant’s reliability, guaranteeing its continual operation for a minimum of 6000 hours non-stop.

Depending on the type of pollutant, its concentration in the gas flow, the expected budget and the line to be served, the company puts forward various solutions, from the optimum in terms of automation, to the most basic function.

TURNKEY PLANT

TURNKEY INSTALLATION

BICARMILL® – MILLING AND INJECTION SYSTEM DESIGNED SPECIFICALLY FOR THE PROCESSING OF SODIUM BICARBONATE

MILL COMPACT, SIMPLE AND ECONOMICAL

GRINDING MILL SUITABLE FOR INSTALLATIONS IN REVAMPING

BICARMILL® – MILLING AND INJECTION SYSTEM DESIGNED SPECIFICALLY FOR THE PROCESSING OF SODIUM BICARBONATE

SINGLE MACHINE UP TO 5 LINES OF INJECTION

MICRODOSER, REAGENT INJECTION WITH COMPRESSED AIR

MICRODOSER, REAGENT INJECTION WITH PUMP

MICRODOSER DOUBLE

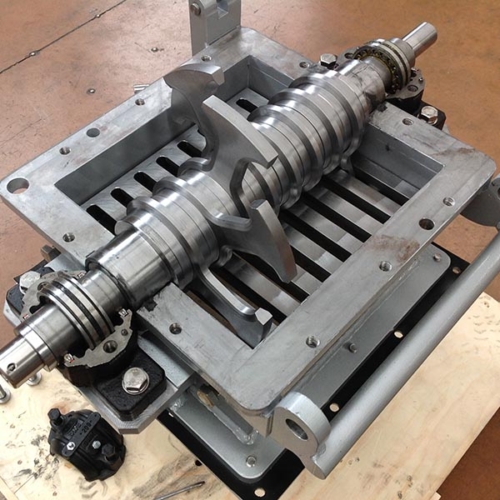

CRUSHER MILL

| Combustion plants | Sodium Bicarbonate Technical Grade (Grinding plant reagent) | Activated Carbon (Dosing and injection) | Products ready to use (lime, calcium carbonate, etc. ..) (Dosing and injection) | BSC – Sodium bicarbonate additivated activated carbon (Dosing and injection) |

|---|---|---|---|---|

| PRIVATE ACTIVITIES, THERMAL COMBUSTION INDUSTRIAL WASTE | * | * | * | |

| BIOMASS | * | * | ||

| CEMENT | * | |||

| COAL FIRED POWER PLANTS | * | * | ||

| WATER PURIFICATION | * | * | ||

| FOUNDRIES METAL RECOVERY | * | * | * | |

| CREMATORIA | * | * | ||

| THERMAL COMBUSTION PLANTS IN GENERAL, FUEL OIL AND NATURAL GAS | * | * | * | |

| MSW INCINERATORS OF MUNICIPAL SOLID WASTE AND HOSPITAL RSO | * | * | ||

| TREATMENT OF HAZARDOUS WASTE | * | * | ||

| GLASSWARE | * | * | * |

Discover our installations around the world.

Discover our installations around the world.