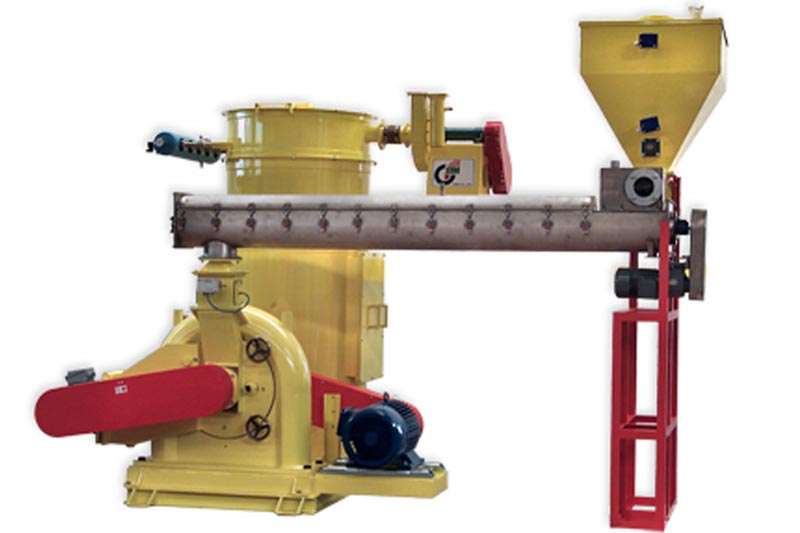

STM equipment for cryogenic applications:

Cryogenic grinding

Pulverization processes normally carried out at ambient temperature can be done at cryogenic temperatures, obtaining higher quality ground products and reducing energy costs.

Heat-sensitive substances with low softening points such as elastomers, rubbers, resins and oily products, can be milled effectively by the use of liquid nitrogen to bring them to their brittle temperature.

Certain materials which cannot be processed in conventional-type mills can now be ground cryogenically.

Liquid or gaseous nitrogen

Liquid nitrogen has three main functions

- Rapidly cools materials to brittle temperature before introduction into the mill

- Maintains a constant working temperature by absorbing heat produced during the grinding process

- Produces an inert, extremely dry and non-toxic atmosphere in the milling plant.

Substances ground cryogenically are physically different from those ground using traditional methods, because of the way in which the material’s structure is broken down.

Substances which have been made brittle cryogenically display homogeneous, crystalline cubic grains: milling at ambient temperature, however, results in powders whose physical properties are non-uniform, because the initial matrix is continually damaged by the flow of crystal planes or the reticular structure of the material.

Uses and Advantages

Cryogenic grinding can be successfully and economically used in the milling of elastomer waste, plastic materials and in all fields where organoleptic, physical or chemical properties need to be blocked cryogenically and maintained in the final product.

Positive factors of cryogenic grinding are:

- Higher yield

- Better quality end product, without abnormal tearing or breakdown in the molecular structure

- Reduction in energy use

- Higher quality end product

- Less waste from oxidation and overheating

- Finer and more homogeneous product

- Reduction in material to be re-processed in the milling system

The quantity of liquid nitrogen used in cryogenic grinding processes is a fundamental consideration when evaluating for or against; this varies according to the materials processed.

Organic Substances

Various combustible, combustive and organic materials can be processed easily and safely, resulting in products which retain not only their physical properties but also their chemical and organoleptic qualities.

The design of our machinery conforms to current ATEX (anti-explosion) legislation, using nitrogen gas as a de-activating agent.

| Tipo Prodotto | Produzione kg/h | Finezza in µ | Temperatura °C | Consumo d’azoto l/kg |

|---|---|---|---|---|

| Anice | 200 | 500 | -15 | 0,9 |

| Benzocaina | 170 | 125 | 0 | 0,8 |

| Hawthorn | 500 | 200 | +5 | 0,5 |

| Roast Coffee | 170 | 50 | -25 | 1,1 |

| Cinnamon | 110 | 200 | +5 | 0,8 |

| Caseine | 400 | 200 | -20 | 0,85 |

| Cephalosporin | 150 | 100 | -15 | 0,5 |

| Cellulose | 80 | 200 | -65 | 2,8 |

| Cloves | 200 | 315 | -5 | 0,9 |

| Cumin | 400 | 400 | 0 | 0,6 |

| Coriandoloer | 550 | 400 | 0 | 0,3 |

| EPDM | 220 | 1000 | -29 | 1,5 |

| Fennell | 330 | 250 | +10 | 0,6 |

| Phytosterol | 250 | 200 | -40 | 1 |

| Cheese | 520 | 400 | +5 | 0,4 |

| Fructose | 300 | 50 | 0 | 0,3 |

| Dried Mushrooms(5mm) | 360 | 160 | 0 | 0,5 |

| Fungicide | 40 | 100 | -20 | 1,8 |

| Gum Arabic | 120 | 50 | 0 | 0,5 |

| Hostalen | 70 | 160 | -60 | 3,3 |

| Sweet Orange | 150 | – | -5 | 1, |

| Methylcellulose | 130 | 200 | -40 | 2,3 |

| Monoglycerides | 150 | 80 | -20 | 0,85 |

| Nutmeg in pieces | 760 | 800 | +10 | 0,3 |

| Nylon 12 | 95 | 400 | -140 | 2,4 |

| Pepper | 500 | 630 | +5 | 0,4 |

| Polyammide | 144 | 200 | -60 | 2,3 |

| Polyammide 6 | 203 | 400 | -60 | 1,4 |

| Polyammide x 2007 | 130 | 800 | -60 | 1,7 |

| Polyester P1500 | 300 | 315 | -15 | 0,7 |

| Polyester S1218 | 140 | 250 | -30 | 1,4 |

| Low Density Polyethylene | 160 | 200 | -30 | 1,5 |

| High Density Polyethylene | 90 | 315 | -60 | 3,2 |

| Polyurethane | 120 | 200 | -45 | 1,6 |

| PVC | 200 | 400 | -15 | 1,2 |

| Hard PVC | 500 | 800 | -10 | 0,6 |

| Epoxy Resins | 400 | 100 | +5 | 0,4 |

| Vinyl Resins (color) | 140 | 400 | -15 | 1,2 |

| Mustard | 220 | 400 | -5 | 0,85 |

| Soy (1 mm) | 600 | 50 | 0 | 0,4 |

| Steroids A | 450 | 32 | 0 | 0,6 |

| Steroids B | 250 | 32 | -20 | 0,9 |

| Sulfadimethoxine | 250 | 50 | -5 | 0,3 |

| TiO2 | 120 | 315 | -15 | 1,1 |

| Vanilla | 180 | 300 | -45 | 1,5 |

| Vestamid T170 | 130 | 200 | -70 | 1,8 |

| Vestamid T250M | 192 | 200 | -60 | 1,9 |

| Viton | 70 | 200 | -20 | 3, |

| Ginger | 480 | 400 | +5 | 0,4 |

| Sulfur | 850 | 40 | 0 | 0,4 |

Discover our installations around the world.

Discover our installations around the world.