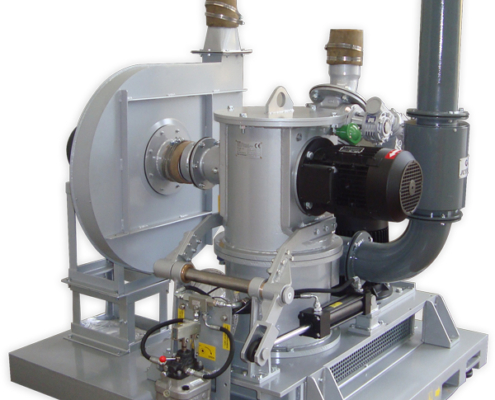

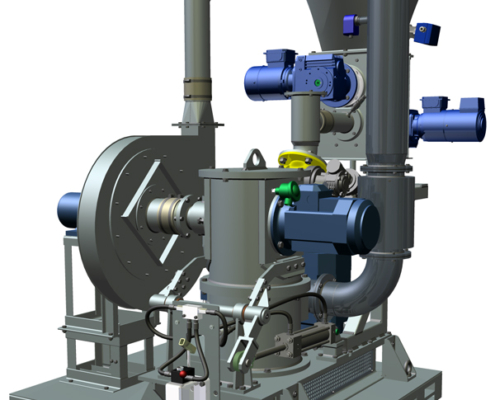

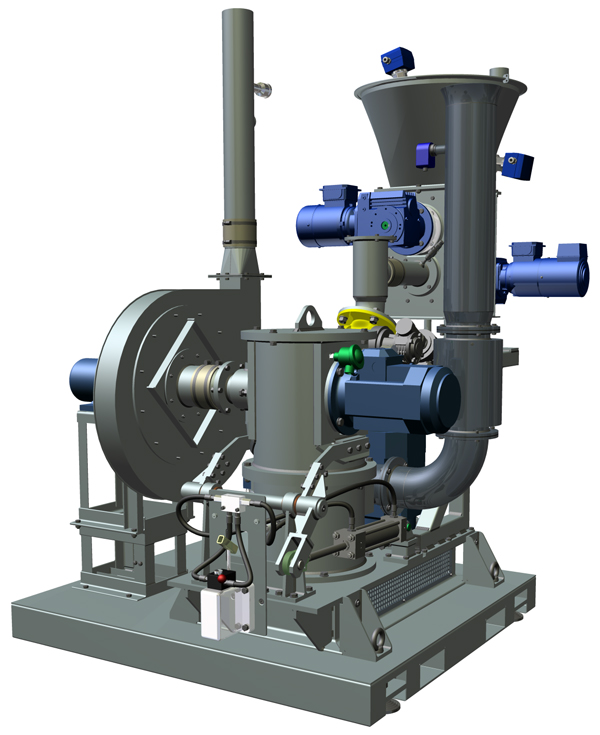

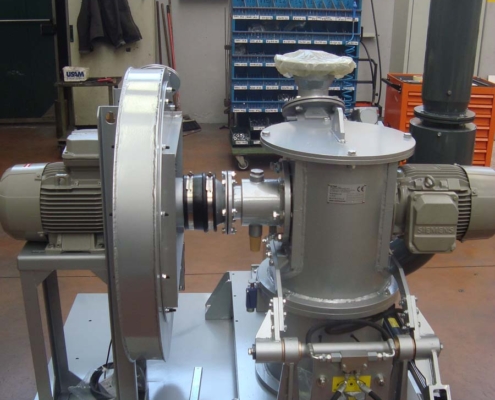

Operational principle

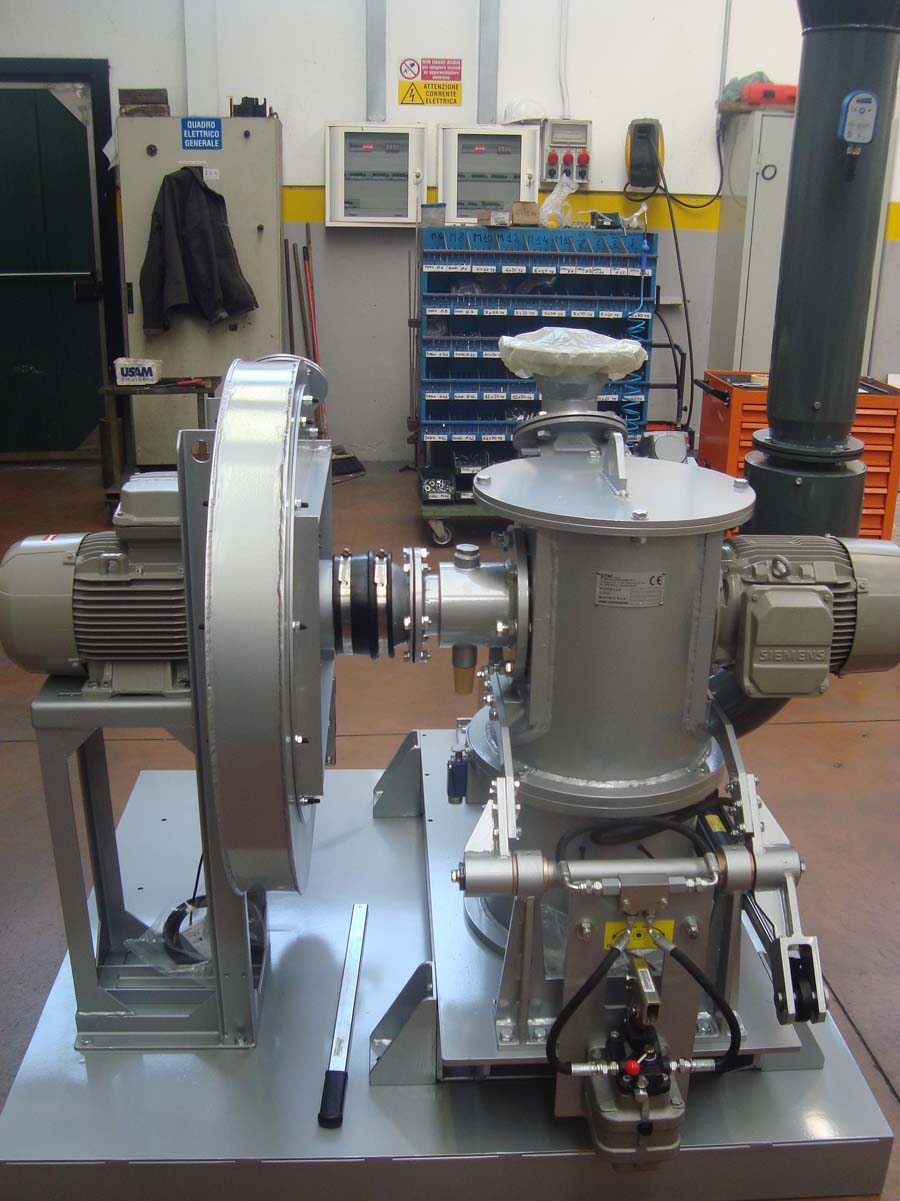

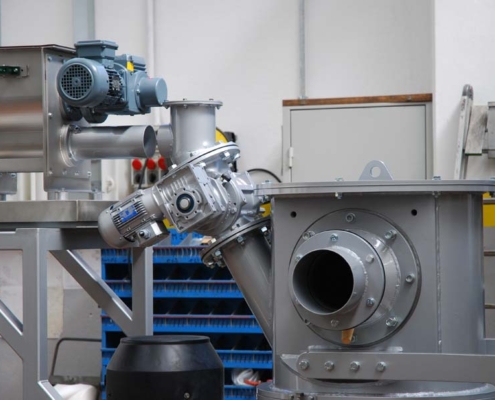

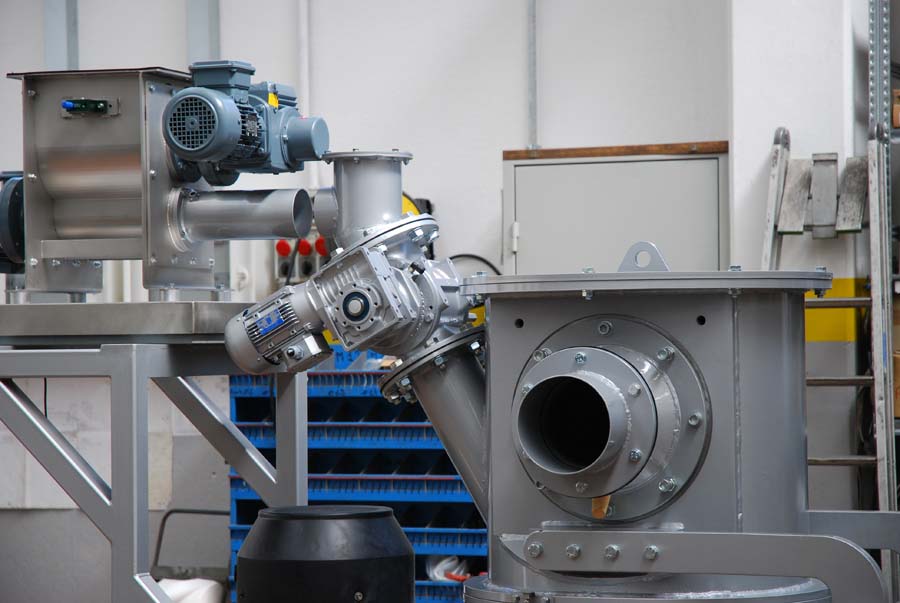

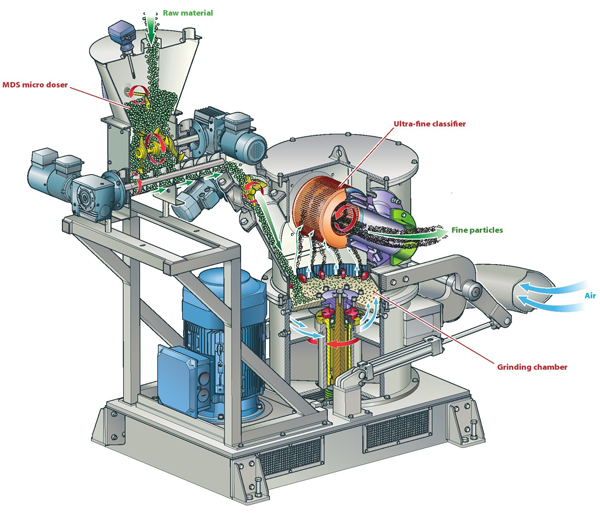

The product to be milled is introduced into the grinding chamber from above, via a screw feed with variable capacity, and then by star valves which insert the product directly into the centre of the impact chamber.

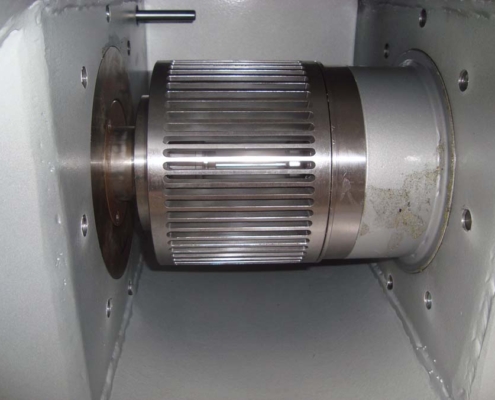

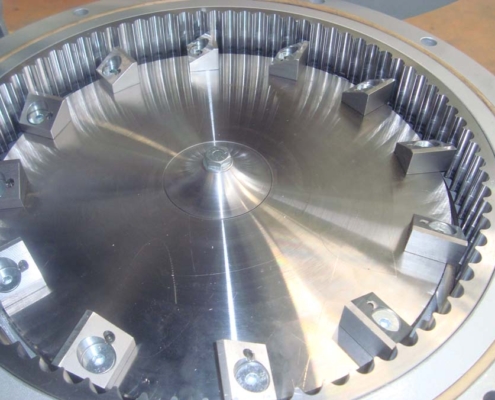

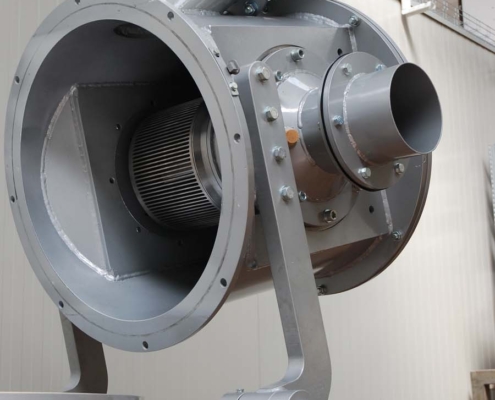

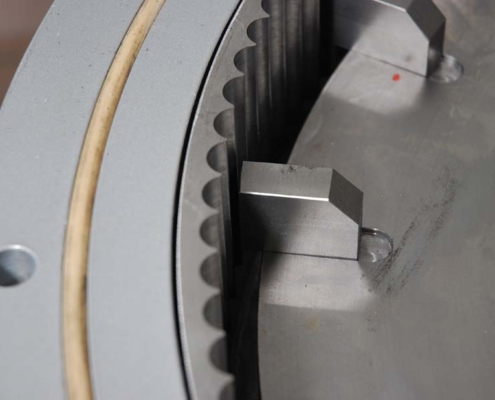

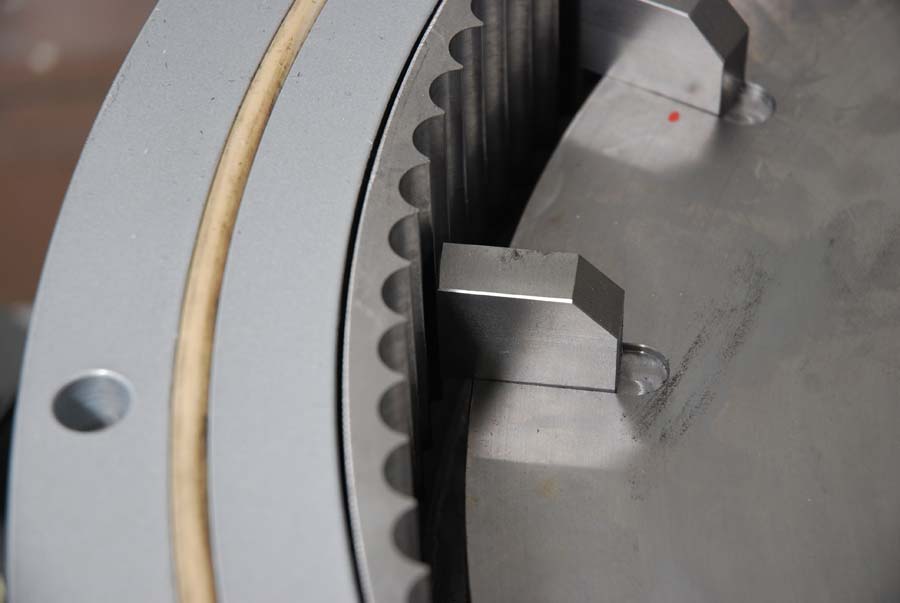

Here the particles smash against each other and against the grinding parts; for a more efficient grinding action, the material is subjected to collision, friction and cutting in the space between the grinding mechanism and the toothed lining of the chamber.

The milled material is conveyed via an extraction fan to the ultra-fine classifier, adjustable by rotation speed, passing through the selected sieve.

By passing through the selection sieve, the material which has not yet reached the desired fineness is sent back into the chamber for a further cycle of grinding, while the product which is sucked into the transport tube is exactly the correct fineness, without waste or loss of material.

Discover our installations around the world.

Discover our installations around the world.